Nagami and Hassell joined forces with creative collective to.org to develop a prototype for a 3D-printed public pavilion made from recycled plastic. Inspired by indigenous shelters, the prototype serves as a gathering point for reflection and education and can be easily modified to suit a range of extreme climates and settings

PLASTIC AS AN INEXHAUSTIBLE BUILDING MATERIAL

The concept for the pavilion was born from an encounter between Hassell’s Head of Design, Xavier De Kestelier, Manuel Jimenez Garcia, founder of Nagami, an additive manufacturing specialist, and Nachson Mimran, Co-founder & Creative Executive Officer of to.org. Together, the team sought to confront the global challenge of plastic waste by setting a precedent that spotlights plastic refuse as an inexhaustible construction material.

Manuel Jimenez Garcia elaborates: ‘We have more than 5 billion metric tons of plastic waste on our planet. As 3D printing scales up into architecture and construction, we can massively increase the demand for recycled plastics and speed up the cleaning process of our oceans and landfills. We hope this project will contribute to inspiring a new generation of architects to truly believe that a radical change in construction, driven by eco-innovation, is truly possible.’

HIGHLY CUSTOMIZABLE, LOW-COST, & CLIMATE-ADAPTIVE

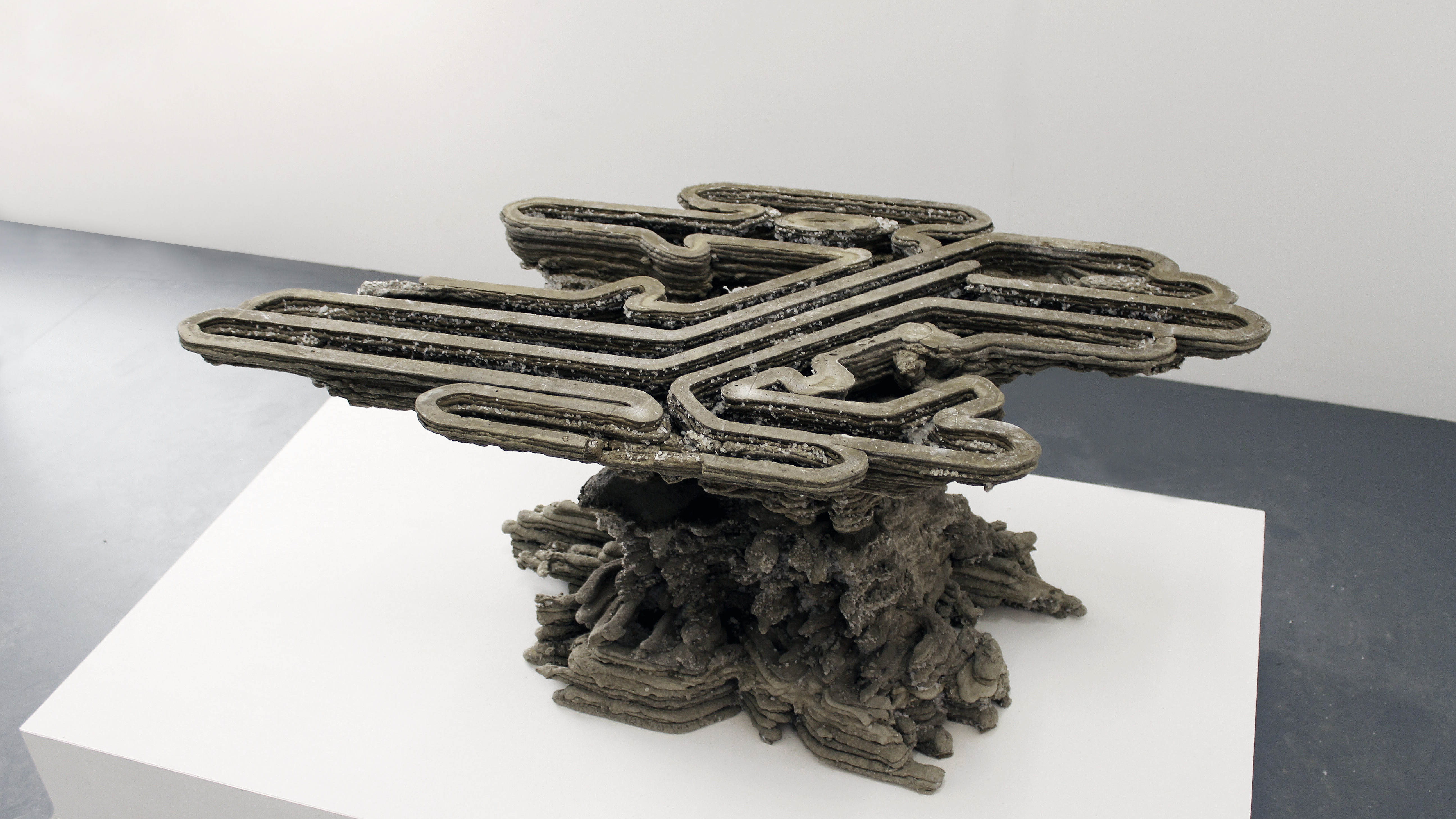

HASSELL and Nagami led the design using computational techniques and resorted solely to 3D printing for fabrication — allowing the public Pavilion to be customized at almost no extra cost to match local climatic conditions.

More specifically, the resulting prototype can be easily transported and assembled on-site, with the main structure 3D-printed in 24 separate pieces. Currently, under construction at the Nagami factory in Spain, the design also includes inbuilt seating for increased capacity.